Koenig & Bauer – Hot-Foil Systems – hpdSYSTEM

For first-class printing results in product coding, the hot foil coding process has been a trusted system for years offering good economic efficiency and operating security. hpdSYSTEM printers offer both brilliant print results and unbeatable robustness and service life. The Koenig & Bauer Coding portfolio meets your individual coding needs and space requirements with the right model for any application.

The use is resulting in a considerable reduction of verification and production costs for the tire manufacturers.

Key Features

- Hot foil coding system

- Very large print area

Available Models

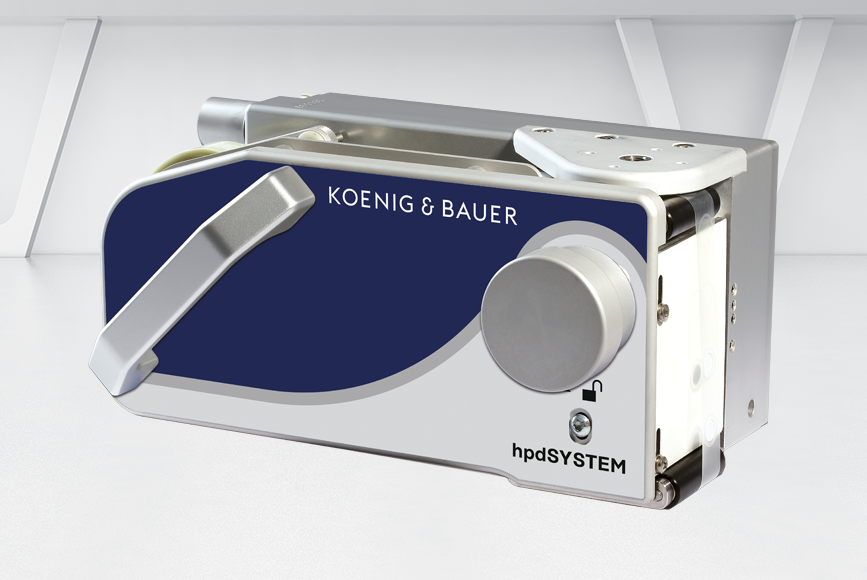

Hot foil printing mechanism with side button. The unique feature of this system is an extremely large print surface stretching to the edge of the product.

- Increase your productivity by reducing downtime due to highest dependability.

- The intelligently configured components increase the lifetime and printing performance.

- The hot foil coding systems hpdSYSTEM are designed for constant use day in, day out and boast high functionality, easy operation, low maintenance and a long working life.

- Hot foil prints adhere to almost all materials, they are smudge-proof and scratch-resistant and can be processed further immediately after printing.

- Whenever top printing quality is demanded, the hot foil process often delivers the best, the easiest and the most favorable solution of product marking.

- Tailor-made to meet large printing requirements right into the edges of the products.

Key Features

- Hot foil coding system

- Very large print area

Technical Specifications

| Print surface max. | 50 x 80 mm |

| Print speed max. | 200 prints / minute |

| Print time | 70 – 2,000 ms |

| Temperature | 50 – 200 °C |

| Print pressure | 1170 N at 6 bar |

| Foil length | 305 m |

| Foil diameter (max.) | 110 mm |

| Foil feed | 2 – 50 mm infinitely adjustable |

| Embossing foil | Yes |

| Premium foil | No |

| Transfer label | No |

| Available options | Sequence control |

| Mains voltage | 24 V DC / 170 VA |

| Heating power | 160 W |

| Compressed air supply | 4 – 6 bar, ø 6 mm |

| Compressed air consumption | 0.25 L per print |

| Dimensions (H x W x L) | 188 x 335 x 169 mm |

| Weight | 8.6 kg |

The hot foil printers hpdSYSTEM moto are used for dot markings in the tire production process. The use is resulting in a considerable reduction of verification and production costs for the tire manufacturers. The heat activated and heat deformable transfer-labels (LTA) “labelDOT” provide excellent abrasion behaviour and high scratch resistance.

- Right- and left-hand version available.

- Additional exchange cassettes for shortest set-up time.

- Compact dimensions: one control unit for up to two printers.

- The hpdSYSTEM moto sets standards: in printing quality, confidence, usability and design.

- 4 systems in one testing device for maximum flexibility.

- Precise marking during the manufacturing stage.

Key Features

- Hot foil coding system with cassette

- For special applications

Technical Specifications

| Print surface max. | 20 x 20 mm |

| Print speed max. | 60 prints / minute |

| Print time | 20 – 2,000 ms |

| Temperature | 50 – 220 °C |

| Print pressure | 580 N at 6 bar |

| Foil length | – |

| Foil diameter (max.) | 100 mm |

| Foil feed | Automatic |

| Embossing foil | Yes |

| Premium foil | Yes |

| Transfer label | Yes |

| Available options | Exchange cassette |

| Mains voltage | 24 V DC / 130 VA |

| Heating power | 120 W |

| Compressed air supply | 3 – 6 bar, ø 6 mm |

| Compressed air consumption | 0.16 L per print |

| Dimensions (H x W x L) | 146 x 293 x 176 mm |

| Weight | 8 kg |

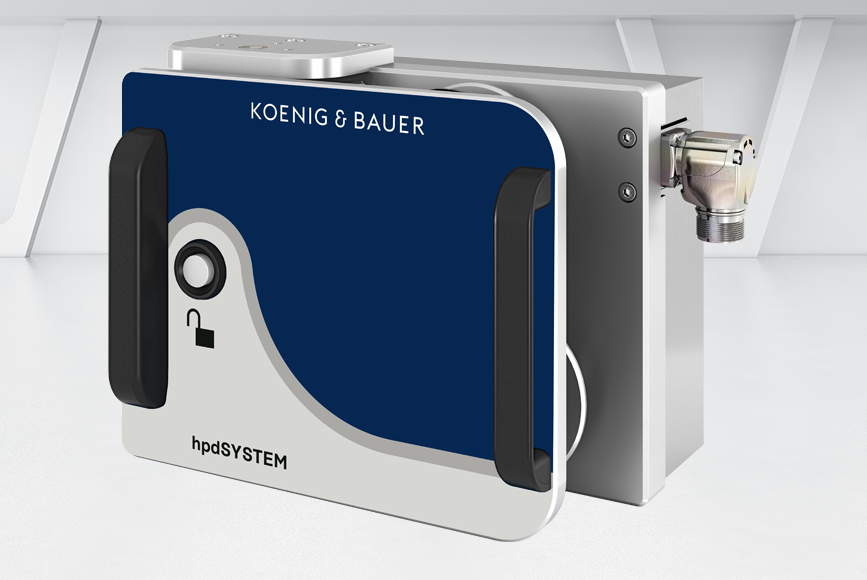

The hot foil printer hpdSYSTEM nano is ideal for use within packaging machines and use within labellers with small space.

- The use of numerators is possible

- Vertical and horizontal version.

- Horizontal version comes with right or left orientation

- The hot foil unit’s compact design and the mounting systems developed by KBA-Metronic, allow these units to be integrated into just about any automatic packaging system, labeling system and post-press machines.

- hpdSYSTEM nano systems are designed for permanent operations and are characterized by significant functionalities, easy operation and a long working life.

- Operation of 2 printers with 1 control unit

Key Features

- Miniature hot foil printer

- For use within packaging machines

- For use within labellers

Technical Specifications

| Print surface max. | 15 x 30 mm |

| Print speed max. | 500 prints / minute |

| Print time | 50 – 2,000 ms |

| Temperature | 50 – 200 °C |

| Print pressure | 373 N at 6 bar |

| Foil length | 122 m |

| Foil diameter (max.) | 72 mm |

| Foil feed | 2 – 15 mm infinitely adjustable |

| Embossing foil | Yes |

| Premium foil | Yes |

| Transfer label | No |

| Available options | IP 65 |

| Mains voltage | 24 V DC / 90 VA |

| Heating power | 80 W |

| Compressed air supply | 4 – 6 bar, ø 6 mm |

| Compressed air consumption | 0.11 L per print |

| Dimensions (H x W x L) | V: 270 x 88 x 129 mm H: 142 x 235 x 127 mm |

| Weight | 3.7 kg |

The hot foil cassette device stands out with quick cycle times and easy handling using a foil cassette. The cassette is very easy to fit with coloured foil outside of the printing mechanism. For even quicker foil exchanges, simply add an exchange cassette to the printer.

- With hpdSYSTEM vario systems there are scores of hot foils in a variety of colours – including spot colours – and different qualities available.

- Magnesium or silicone embossing plates are produced in the in-house engraving manufacture as well as steel or brass print type according to your specifications: Custom Fonts, logos, or drawings – quickly, reliably, and guaranteed.

- The hot foil coding systems hpdSYSTEM are designed for constant use day in, day out and boast high functionality, easy operation, low maintenance and a long working life.

- With up to 1,000 prints/minute.

- Large portfolio of printer options, you remain extremely flexible in terms of print area, left or right orientation and size ratio.

- Reduce your setup time with exchange cassettes.

Key Features

- Miniature hot foil printer

- For individual product coding

- Up to 1,000 prints/min.

Technical Specifications

| Print surface max. | 30 x 50 mm |

| Print speed max. | 1,000 prints / minute |

| Print time | 20 – 2,000 ms |

| Temperature | 50 – 220 °C |

| Print pressure | 580 N at 6 bar |

| Foil length | 305 m |

| Foil diameter (max.) | 100 mm |

| Foil feed | 2 – 30 mm infinitely adjustable |

| Embossing foil | Yes |

| Premium foil | No |

| Transfer label | No |

| Available options | V: IP 65 / H: IP 54, sequence control, core scanning, exchange cassette |

| Mains voltage | 24 V DC / 130 VA |

| Heating power | 120 W |

| Compressed air supply | 4 – 6 bar, ø 6 mm |

| Compressed air consumption | 0.16 L per print |

| Dimensions (H x W x L) | V: 206 x 190 x 166 mm H: 142 x 285 x 166 mm |

| Weight | 6.7 kg |

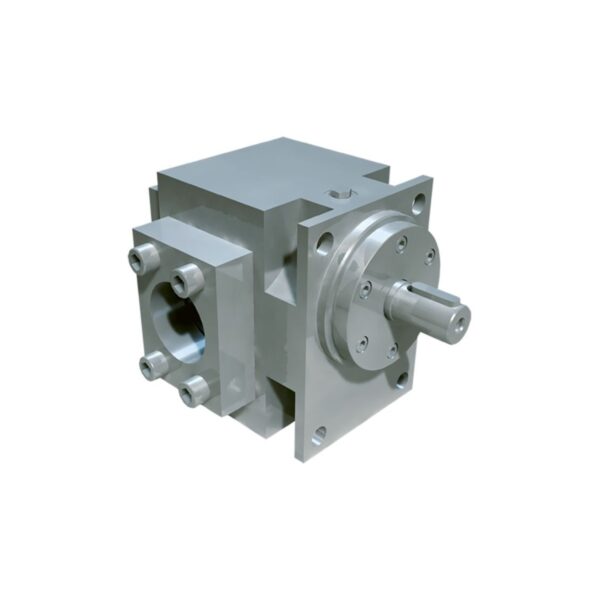

Various markets and customers require even higher flexibility in terms of coding and marking. The hpdSYSTEM TR impresses in this area with its rotating printing wheel that can print up to 8 symbols per printing unit. This increases your flexibility and reduces the need for larger numbers of marking devices. In combination with the recently developed premium foil, excellent print quality can be achieved on the tire sidewalls, which adheres very consistently to the tire. In addition to the familiar marking symbols, logos and letters (e.g. P, PP, N, NN) can also be applied perfectly to the tires.

- Printing wheel that can print up to 8 symbols per printing unit.

- In combination with the recently developed premium foil, excellent print quality can be achieved on the tire sidewalls, which adheres very consistently to the tire.

- In addition to the familiar marking symbols, logos and letters (e.g. P, PP, N, NN) can also be applied perfectly to the tires.

Key Features

- Low consumption combined with low prices to save money.

- Excellent uptime of over 99 % provides true production reliability.

- Easy integration and high-speed printing increase your productivity.

- A variety of colour foils lets you react flexibly to customer requests and increases customer loyalty.

Technical Specifications

| Print surface max. | 15 x 15 mm |

| Print speed max. | 5 prints / minute |

| Hot foil length | 183 m |

| Premium hot foil length | 65 m |

| Foil Diameter ( max.) | 85 mm |

| Hot foil | Yes |

| Premium hot foil | Yes |

| Transfer label (LTA) | No |

| Available options | Protection class IP 20, exchange cassette |

| Mains voltage | 24 V DC / 130 VA |

| Heating power | 120 W |

| Compressed air supply | 2 – 6 bar, ø 6 mm |

| Compressed air consumption | 0.16 L per print |

| Dimensions (H x W x L) | 210 x 305 x 180 mm |

| Weight | 10.5 kg |

Key Industries

- Automotive

- Cosmetics and Personal Care

- Food and Beverage

- Machinery and Manufacturing

- Pharmaceutical

Koenig & Bauer Coding specializes in the development, design, production and marketing of printing, coding and marking technology, the company…

-

High-Quality Coding Solutions Brochure – Koenig & Bauer Coding GmbH

INDONESIA

PT. DKSH Market Expansion Services Indonesia

AIA Central 39th floor. Jalan Jenderal Sudirman Kavling 48A

12930 Jakarta Selatan

Indonesia

+62 878 5851 0022

+62 21 2988 8557

Download now

How to Disable Pop-Up Blockers for Smooth Downloads

Google Chrome (Version 110 and later):

- Click the three dots (menu) in the top-right corner and select Settings.

- Under Privacy and Security, click Site settings.

- Scroll down to Content and click Pop-ups and redirects.

- Toggle the switch to Allowed or add https://technology-products.dksh.id to the Allow list.

Mozilla Firefox (Version 90 and later):

- Click the three horizontal lines (menu) in the top-right corner and select Settings.

- Go to the Privacy & Security section.

- Scroll to Permissions and uncheck Block pop-up windows for https://technology-products.dksh.id.

Microsoft Edge (Version 110 and later):

- Click the three dots (menu) in the top-right corner and select Settings.

- Scroll down to Cookies and site permissions.

- Under Site permissions, click Pop-ups and redirects.

- Toggle the switch to Allow or add https://technology-products.dksh.id to the Allow list.

Safari (Version 14 and later):

- Open Safari and go to Preferences (from the top menu).

- Select the Websites tab.

- Under Pop-up Windows, select Allow for https://technology-products.dksh.id.