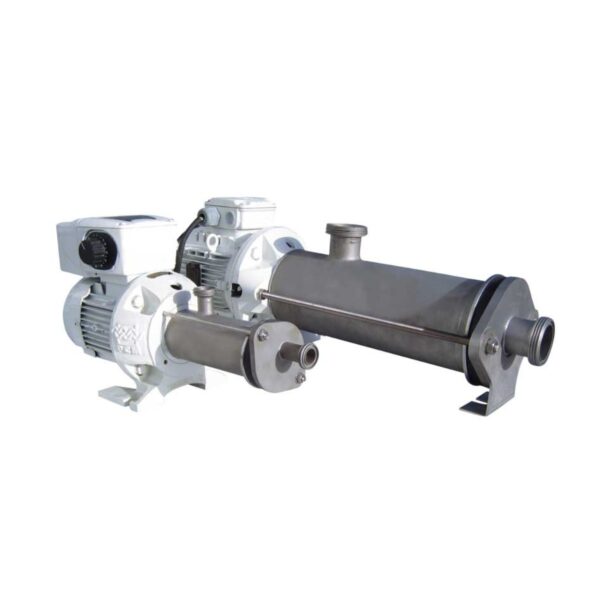

PCM – Progressing Cavity Pump

Founder of the PCM company in 1932, René Moineau is the inventor of the Progressing cavity pump, also known as Moineau pump. A Moineau™ progressing cavity pump consists of a helical rotor, which turns inside a helical stator.

The stainless steel rotor is machined to a high degree of precision, and the stator is moulded in a resilient elastomer. This means that when the rotor is inserted into the stator, a double chain of honeycombed-shaped watertight cavities is created. When the rotor turns inside the stator, the honeycomb moves spirally along the axis of the pump, never changing shape or volume. This allows the product to be transferred from the pump intake to the pump discharge, without any degradation.

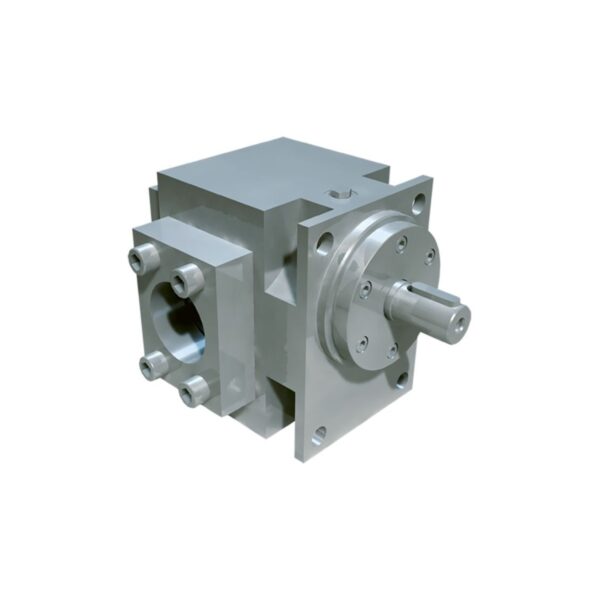

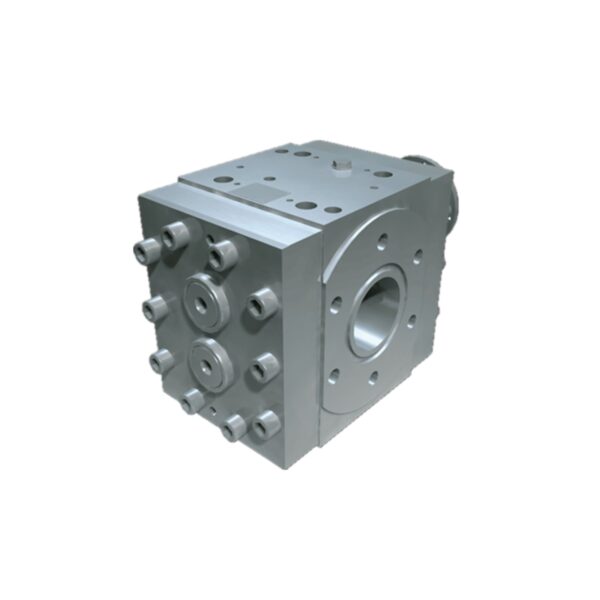

Available Models

More Products

For more than 90 years, PCM has been delivering high quality and cost effective fluid handling solutions. With DKSH, PCM…